Autodesk

I had the privilege of working as an interaction design intern at Autodesk during summer 2015. We spent the first part of the internship researching topics such as energy, synthetic biology, and augmented reality to inspire concepts, which were then translated into stories that we pitched. The best story would be selected to be developed into a short story, illustrated, and prototyped with 3D models.

I worked with 3 other interns - an illustrator, a storywriter and an architect, and we all contributed to envisioning the stories. Although the medium of the deliverables varied, they would all fit into the world of the story, and it was awesome to see the other 3 interns' work all come together to visualise the same world.

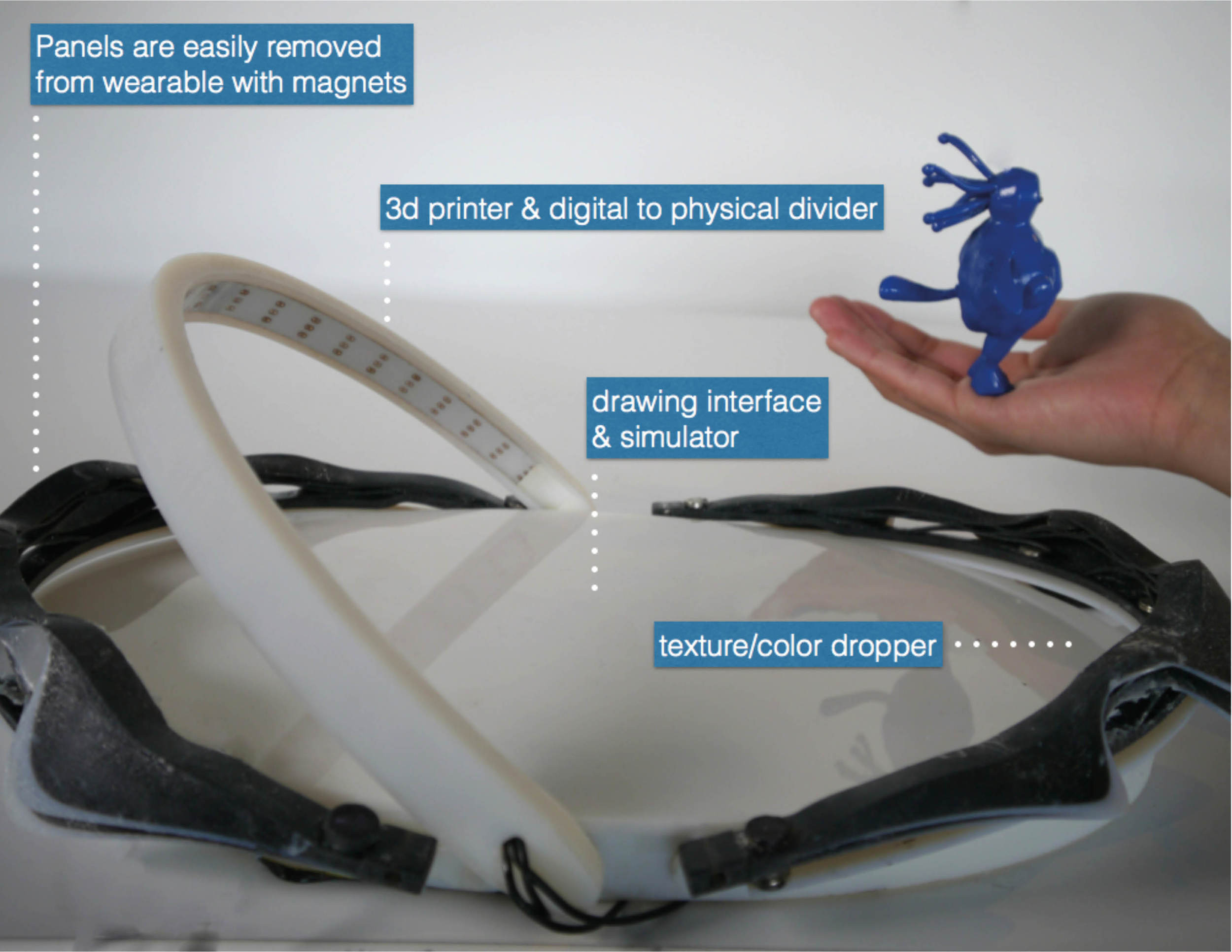

For the second half of the internship, we compiled all the ideas we liked from previous story pitches, whether they were characters, themes or concepts, and integrated them into a final story to be developed further. We decided to focus on the theme of the intersection of design and technology in the future. I created a head-mounted, multi-material 3D printed wearable that links a child to her imaginary friend in the story. The wearable has pneumatic silicone actuators that I cast by lasercutting molds from acrylic.

The password is "12345".

This is a short design fiction video telling a story about a child growing up in the future of design and technology. The video shows the interactions of how a child might design a toy in the future with improved computer aided design. The head-mounted wearable bridges the gap between the physical and virtual environments of the child by capturing brain activity and finds a reciprocal relationship between her imagination and the real world.

Part of the wearable can be removed and connected to a drawing board, where Millie shows Finn her designs. The drawing board can simulate her drawings, demonstrating to Millie that the creature she originally drew is not balanced, and therefore cannot walk. Millie is able to edit her 2D drawing, giving it a tail for balance. The design is then 3D printed for her, where she can continue to edit it, and transfer it seamlessly between the 2D and 3D model.

This short scene falls into a larger design fiction story, illustrated by another intern. In the broader story, a young girl named Millie is only five years old when her parents are going through a divorce. Millie is given a wearable created by her father that allows her to interface with her imaginary friend, Finn. Finn helps Millie cope with her parents' divorce by being her friend. In the beautifully illustrated comic, Millie interacts with Finn through the internet of things. Millie is only able to see Finn when she has the wearable on, but he is able to communicate to her through things like projecting himself onto her window and moving the wearable up and down when it is resting on a table to get her attention.

These small nudges allow them to live in symbiosis, without him invading her personal space. Finn helps Millie design a fantasy world together, where Millie draws her designs and Finn simulates them with a drawing board. In the real world, they are playing with cardboard boxes, but in the virtual world, Millie and Finn see an intricate city with lights.

Review of the Video Here

process - Experiments with Silicone Behaviour

I experimented with embedding different shapes within the silicone to see how it affected the inflation. I found that it was difficult to get the same results even when repeating the same process, because the silicone was very sensitive to even minute changes. Air would also escape if the silicone were not completely air tight, making the inflation patterns change over time. Silicone is very difficult to adhere to other materials besides itself, and that even with silicone-specific glue, breakage and rips would occur after multiple inflations if the silicone were too thin. It was really interesting to see how silicone behaves since the effect is organic, unpredictable and unique. We also tested the flexibility of multimaterials and frequency of nodes for 3D printing. We tried embedding different materials in the silicone to see how it would react when inflated, as well as casting different shapes and thicknesses.